For utilities in the Mid-Atlantic, reliable communication is just as important as reliable power delivery. OPGW (Optical Ground Wire) splicing services play a key role in making that possible. The OPGW combines two functions: it protects the power grid as a ground wire while carrying optical fibers that transmit data for grid monitoring, SCADA systems, and smart grid applications.

When OPGW is installed and repaired, splicing is one of the most critical steps. This process of connecting fiber ends inside the cable has to be performed correctly. A poor splice can cause signal loss, outages, or even grid instability. That’s why choosing the right contractor is one that has proven safety protocols, and has current knowledge of the Mid-Atlantic fiber infrastructure.

This buyer's checklist gives utility procurement teams a structured way to evaluate OPGW splicing contractors, ensuring safe, compliant, and cost-effective OPGW splicing services.

Understanding OPGW Splicing in Utility Operations

OPGW is designed for high-voltage transmission lines. It contains metal strands (for grounding and strength) and fiber optic cables (for communication). Splicing requires opening this cable and joining fibers without damaging the electrical grounding system or reducing line performance.

In the Mid-Atlantic region, which is home to utilities like PECO, BGE, Dominion Energy, and PPL, splicing is especially important for:

- SCADA systems that monitor grid conditions in real time

- Protective relaying that isolates faults to prevent blackouts

- Smart grid functions like distributed energy resource (DER) management

Since the work takes place on high-voltage transmission lines, splicing requires specialized tools, insulated equipment, and strict safety steps. Contractors must also understand protocols of how OPGW should be tested and verified.

IEEE 1138-2021: The Foundation of OPGW Performance Standards

The IEEE 1138-2021 standard is the foundation for OPGW performance and quality. It covers how OPGW should be tested especially for mechanical and optical reliability. Any contractor offering OPGW splicing in the Mid-Atlantic should show documentation that they meet these requirements. Key requirements include:

Mechanical Testing

Mechanical testing verifies that OPGW can withstand the physical stresses of installation and long-term field conditions. These tests ensure the cable maintains structural integrity under load, resists fatigue from vibration, and performs safely during handling and deployment. Things to keep in mind include:

- Tensile strength (minimum 40% of rated breaking strength) and bending resistance

- Fatigue testing under vibration

- Safe load limits during installation

Optical Testing

Optical testing confirms that OPGW meets performance standards for signal transmission and reliability. These evaluations measure fiber attenuation, splice quality, and return loss to ensure minimal signal degradation, while also verifying durability under environmental stresses in compliance with IEEE 1138-2021. Things to keep in mind include:

- Fiber attenuation limits (≤0.4 dB/km at 1310 nm, ≤0.3 dB/km at 1550 nm)

- Splice loss limits (≤0.1 dB average)

- Return loss requirements and environmental durability

Critical Safety Protocols for OPGW Splicing

Since splicing occurs on or near live, not dark, cable lines, safety is paramount. Leading contractors use detailed Job Safety Analysis (JSA) documents to map out their work before it begins. This checklist covers weather, site hazards, PPE (Personal Protective Equipment), and emergency planning. Without these safeguards, even the best technical work can put crews and the grid at risk.

Required Safety Equipment Standards

Strict safety standards govern OPGW splicing and installation, requiring crews to be fully equipped with appropriate protective gear and specialized tools. Personal protective equipment (PPE) must include 20kV-rated gloves, arc-rated clothing, electrical hazard (EH) boots, and fall protection systems to ensure worker safety in high-voltage environments. In addition, proper grounding equipment is essential, such as 5/8-inch by 4-foot ground rods, 2/0 grounding cables (67mm²), stirrup clamps, and grip-all clamp sticks ranging from five to eight feet in length. Crews must also use specialized tools to maintain optical integrity and reliability, including fusion splicers, OTDR testers, and weatherproof splice enclosures.

Pre-Work Safety Steps

Before any OPGW work begins, crews must follow strict safety protocols to minimize risk and ensure compliance with established standards. Weather conditions should be closely monitored, and no work should proceed if lightning is detected within a five- to ten-mile radius. All personal protective equipment (PPE) and testing devices must be thoroughly inspected to confirm they are in proper working condition. Site-specific hazards should be reviewed with the team, and rescue procedures along with emergency response plans must be verified to ensure everyone is prepared should an incident occur.

Grounding and Bonding Procedures

Proper grounding and bonding are critical to maintaining worker safety and system reliability during OPGW splicing operations. The OPGW cable must be grounded above all splice points to ensure safe energy dissipation. Personal protective equipment and vehicles should be bonded and positioned at least six feet from the active work area to minimize electrical risk. Crews must use approved ground rods, clamps, and cables to establish secure connections, while also taking steps to reduce step and touch potentials around the work zone to prevent accidental shock hazards.

Mid-Atlantic Regional Considerations

OPGW splicing in the Mid-Atlantic requires careful planning due to the region’s diverse environmental factors, strict regulations, and complex urban infrastructure. From coastal salt air and frequent storms to compliance with multiple state utility commissions and NERC CIP standards, contractors must navigate a range of factors that can impact both safety and reliability.

In densely built areas, additional urban infrastructure challenges such as electromagnetic interference and restricted transmission access further complicate projects. Contractors with local expertise are best positioned to anticipate these challenges, minimize risks, and keep projects on schedule.

Comprehensive Buyer's Checklist for OPGW Splicing Contractors

When evaluating OPGW splicing contractors, procurement teams should look beyond cost alone and assess a full range of qualifications. A reliable partner must demonstrate compliance with industry standards, provide proof of technical expertise, follow rigorous safety practices, and have experience managing the unique environmental and regulatory challenges of the Mid-Atlantic region.

This checklist ensures decision-makers can identify contractors who not only deliver quality work but also reduce risk, avoid delays, and protect long-term system reliability.

Technical Qualifications and Certifications

The key technical qualifications and certifications required for personnel and contractors are essential. Ensuring that team members hold the appropriate credentials is critical not only for compliance with industry standards and safety regulations but also for guaranteeing the quality, reliability, and longevity of the work performed.

Proper qualifications help mitigate risks, prevent costly errors, and instill confidence that projects are executed by trained and competent professionals. They should have:

- OSHA training

- Fiber Optic Association (FOA) certified technicians

- Utility-specific safety certifications

- Fusion splicing expertise with <0.1 dB average loss

Safety Program Evaluation

Safety program evaluation is a critical component of contractor and personnel assessment. Key elements include a written safety management plan, documented JSA procedures, current PPE certifications, and a proven record of low incident rates. Together, these components demonstrate a commitment to workplace safety, regulatory compliance, and risk mitigation, ensuring that all work is conducted in a safe and controlled environment

Project Management and Quality Assurance

Project management and quality assurance are essential to ensure that work is executed efficiently, accurately, and reliably. Key components include detailed work planning and outage coordination, robust quality control processes with comprehensive test reporting, and long-term monitoring with warranty support. Together, these practices help maintain high standards, minimize disruptions, and provide confidence that projects are completed on time and to specification.

Regional Experience and References

Regional experience and references are critical for ensuring successful project execution in the Mid-Atlantic region. Key factors include a history of past projects with local utilities, a thorough understanding of regional environmental and regulatory challenges, and established relationships with local suppliers and subcontractors. Together, these elements demonstrate proven expertise, local knowledge, and the ability to navigate complex regional requirements efficiently and effectively.

Financial Stability and Insurance

Financial stability and insurance are essential indicators of a contractor’s ability to successfully manage and complete large projects. Key elements include strong bonding and comprehensive insurance coverage, a proven track record of financial stability, and transparent payment terms with effective cost management. These factors provide assurance that projects will be executed reliably, risks are mitigated, and financial obligations are met without disruption.

KPIs for OPGW to Track Against

Key performance indicators (KPIs) are essential for tracking OPGW splicing contractor performance and ensuring project success. Important metrics include technical measures such as average split loss below 0.05 dB, and a success rate above 95%. Safety standards should be upheld with zero incidents, full compliance with safety protocols, and current certifications for all staff. Efficiency metrics, including minimal outage durations, rapid restoration times, and reliable scheduling, further ensure that projects are completed safely, on time, and to the highest quality standards.

Cost Considerations and Value Engineering

While price is an important consideration, the lowest bid may cost more in the long run if quality or safety is compromised. Utilities should evaluate direct costs, including labor, equipment, enclosures, testing, and reporting, alongside indirect costs such as outage duration, compliance penalties, and future maintenance requirements.

Value engineering strategies, such as bulk splicing projects, standardized enclosures, preventive maintenance, and the integration of new technologies, can optimize cost efficiency and long-term project performance.

Emerging Technologies and Future Considerations

As the power grid continues to modernize, OPGW splicing is becoming increasingly critical. Utilities face growing demands for faster, safer, and more reliable fiber connections, driving the adoption of advanced splicing technologies.

Automated fusion splicing ensures consistent connections while reducing labor costs, ribbon splicing allows multiple fibers to be joined simultaneously for large projects, and field-installable connectors minimize the need for full splices in certain setups. Remote monitoring further enhances reliability by tracking splice performance in real time and identifying potential issues early.

These technological advancements coincide with broader grid modernization trends, including the integration of 5G for utility communications, management of distributed energy resources that require higher bandwidth, implementation of robust cybersecurity protections for fiber-based systems, and increased focus on climate resilience to withstand severe weather events and support rapid recovery. Contractors who adopt these new splicing methods and monitoring tools play a key role in helping utilities stay ahead of these evolving challenges

Celerity: Trusted OPGW Splicing in the Mid-Atlantic

At Celerity, based in Quakertown, PA, we specialize in OPGW splicing across the Mid-Atlantic region. Our team is fully certified and compliant with JSA procedures, and maintains an exemplary safety record.

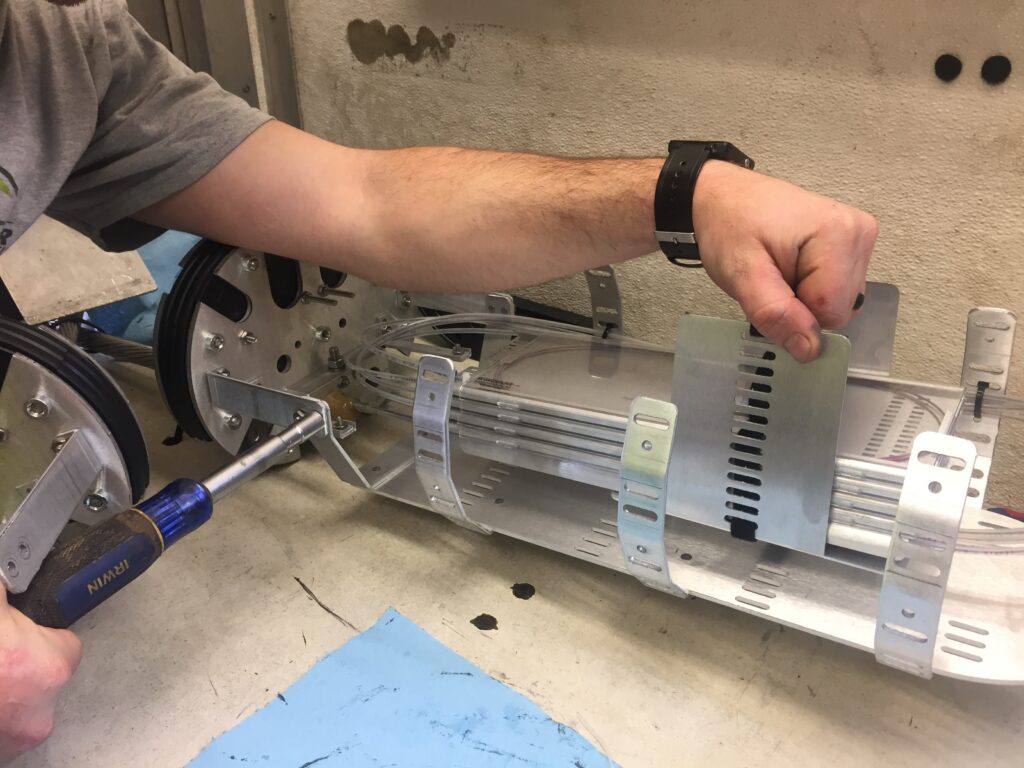

Our Well Crafted installation services include environmentally controlled splicing labs on 4x4 bucket trucks, ensuring precision fiber work in any weather. We have successfully partnered with PECO, BGE, Dominion Energy, and PPL, delivering splice loss averages under 0.05 dB.

With proven expertise, local knowledge, and a strong safety culture, we help utilities reduce downtime, improve grid reliability, and prepare for the future of smart energy.